System that cleans the sedimentation generating a discharge with the waste water retained in an attached chamber (cleaning chamber). This chamber is filled through a vacuum system composed of a diaphragm valve and a suction pump. The system is installed on the outside of the tank, facilitating the maintenance of it, and is able to clean tanks of high lengths

This system has obvious advantages since it is not necessary to supply external water, its maintenance is reduced to a minimum and it can clean longer tank lengths

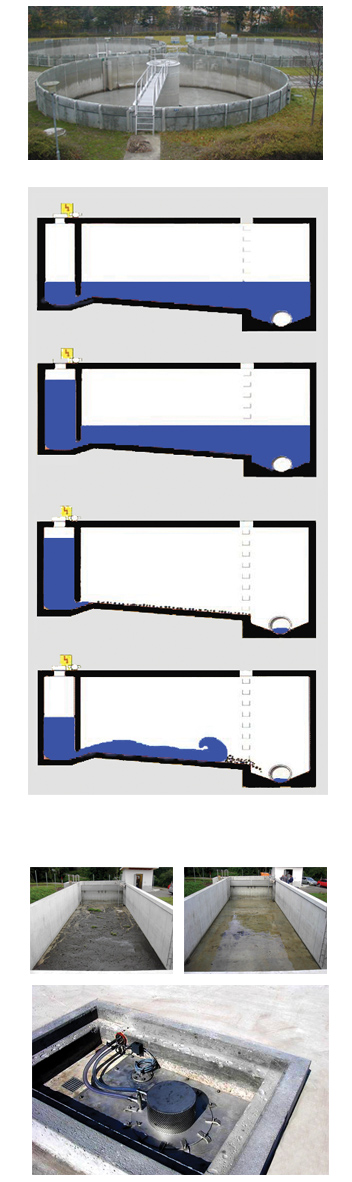

Operation:

Once the system detects the partial or total filling of the retention chamber, the diaphragm valve is inflated. The vacuum pump automatically starts sucking air until it reaches the maximum level in the flushing chamber.

Once it has been detected that the storm has finished and the retention chamber has been emptied, the system releases the water retained in the cleaning chamber, causing an energetic wave that drags the sediments towards the collection channel, to be then conducted to the waste water Treatment Plant

Sizing:

The capacity of the cleaning chamber (m3 / linear meter) required for effective cleaning is calculated according to the dimensions of the retention chamber (length, height), and the slope of the floor.

Depending on the width of the chamber, it is divided into one or several cleaning lines. The maximum width of each cleaning line is 10 meters. For larger widths several cleaning lines should be formed, separating them from each other by means of low concrete walls, preferably ending in a peak to avoid deposition of solids in them.

Components of the system:

- Shipon.

- Vacuum pump

- Membrane

- Sump

An auxiliary system can be included for filling the vacuum chambers to be able to clean the tank even when there is no storm.

In the case of needing several cameras, the siphons must be communicated, and through a single system you can proceed to the alternative filling of each of them, or it is provided to each siphon of your corresponding filling system.

The vacuum system can be used both in existing tanks and in new construction tanks, being of vital importance for its operation the correct execution of the corresponding civil works.

The vacuum cleaning system can be implemented in rectangular, circular tanks or for cleaning sewers.